Recently, the full-chain synthetic biology R&D platform, Synceres, announced the completion of its nearly 100 million yuan of Series A funding, led by Shenzhen Capital Group (SCGC), with participation from Shenzhen HTI Group and multiple downstream investors. This marks the second consecutive investment in Synceres led by SCGC. As revealed by founder Luo XiaoZhou, the funds will be utilized for horizontal expansion and product manufacturing, aiming to cover a wider range of essential product categories. By aligning with market demands, the company aims to "innovate" new products from these premium categories. Previously, Synceres was featured in the “Top 50 Noteworthy Synthetic Biology Companies” list by EB Insights, being one of the nine Chinese companies to make the cut.

Synceres was established in 2019 by Luo Xiaozhou, a researcher at the Research Center of Synthetic Biochemistry, Shenzhen Institutes of Advanced Technology, Chinese Academy of Sciences. It focuses on the research and development of synthetic biotechnology and its innovative application in many fields such as medicine, chemical industry, agriculture and consumer goods, and strives to contribute to the realization of the country’s "carbon neutrality” goals. To date, Synceres has achieved several breakthroughs in manufacturing techniques of synthetic biology, and established classis cell structures for multiple sub-categories, laying groundwork for the development of nearly 10 products in the upcoming 2 years.

Taking this opportunity, SciPhi-SynBio invited Luo XiaoZhou, the founder of Synceres, to share his entrepreneurial experience and the company's future plans.

Picture 丨 Luo Xiaozhou (Source: from the interviewee)

Combining Academic Research with Industrial Application to Promote Full-chain R&D

“Since its inception, Synceres has been aware of its mission: to synthesize the world's essential raw materials and contribute to society. Our end goal is always product delivery,” said Luo XiaoZhou.

Luo XiaoZhou obtained his bachelor’s degree from Nanyang Technological University in Singapore, pursued his Ph.D. at The Scripps Research Institute in the US, and later conducted post-doctoral research under Jay D. Keasling at UC Berkeley. His current research focuses on directed protein evolution based on big data and machine learning, protein engineering, high-throughput screening, and the biosynthesis of natural and non-natural compounds.

In 2019, Luo XiaoZhou returned to China, taking on the role of Executive Director at the Synthetic Biochemistry Center of the Shenzhen Institutes of Advanced Technology, China Academy of Sciences while founding Synceres. He believed that wearing both hats enabled him to effectively bridge the gap between the pursuit of innovation of academic institutions and the commercial demands of companies.

Luo XiaoZhou expressed that these dual roles formed a clever combination, effectively narrowing the gap between research and industrialization, empowering Synceres to develop a full-chain synthetic biology R&D platform. This full-chain R&D spans three phases: 0-1 for academic research, 1-10 for engineering R&D, and 10-infinity for industrial scale-up.

He added, "Scientific research is more about going from 0 to 1, while the company focuses on scaling from 1 to 10 and then 10 to infinity in terms of industrial scale-up. Holding positions in both areas allows me to bridge them effectively. As a researcher, I am acutely aware of the challenges faced in translating scientific research into industrial applications. As the founder of a company, I can keenly identify business needs, secure commercial orders, and relay R&D requirements back to research institutions, seamlessly bridging the entire process from inception to commercialization. "

Developing a Full-chain Synthetic Biology R&D Platform in Three Years with 20 R&D Techniques

Since its establishment in 2019, Synceres has built a full-chain R&D platform for synthetic biology based on synthetic biotechnology. The base for development of the platform is the numerous essential synthetic biology R&D techniques developed by the company. Techniques refer to the standard procedures and norms referenced to achieve specific goals. Specifically, it dictates which key technologies are needed at every R&D step. These technologies include high-throughput screening and AI machine learning.

In the past three years, Synceres has developed nearly 20 R&D techniques from optimizing three elements including enzymes, promoters and regulatory elements, optimizing the entire pathway to optimizing the whole strain. These techniques, seamlessly integrated with automation facilities and machine learning capabilities, have brought numerous advantages to Synceres in producing high-value-added products.

“First of all, it can increase throughput and result in a speed boost.” Luo Xiaozhou provided two examples. The first example is to optimize the pathway of flavonoids production using the bottleneck procedures. In the past, the yield of flavonoids was only a few milligrams. However, by modifying the enzymes in this pathway, Synceres boosted the production by ten times within six months.

The second case is to improve the stability of protein. As traditional methods are adopted, extensive screening is required, taking up to three months, to improve protein stability by 2-3 degrees. Now, with unsupervised deep learning algorithms, it's possible to predict which enzyme mutants are more stable. By utilizing automated equipment to construct and test them, and after multiple iterations, the original three-month R&D techniques can be optimized and reduced to just two weeks, significantly increasing the success rate of the entire workflow.

“Furthermore, with these techniques in place, we can determine the time, cost, and success rate of each procedure. Through long-term statistics, we can roughly estimate the timeline required to achieve a specific goal, transforming a relatively uncertain scientific research problem into a more deterministic engineering problem.”

By utilizing these 20 R&D techniques to improve various enzymes and optimize different pathways, combined with high-throughput automation and machine learning, Synceres has accumulated a dozen strains based on various biosynthetic pathways.

These chassis strains, which are of a higher dimension and closer to the final product strains, including brewing yeast, corynebacterium glutamicum, and streptomycetes, cover essential directions of synthetic biology products such as terpenoids, alkaloids, fatty acids, amino acids, and flavonoids.

With numerous standardized techniques and advanced chassis strains, Synceres can rapidly expand its R&D scale and improve R&D efficiency. The increased R&D scale and efficiency will lead to more products, fulfilling the demands of more downstream users. As sales and products grow, techniques will undergo further optimization, enhancing both R&D scale and efficiency, achieving a seamless closed loop.

Picture 丨 Brewing Yeast (Source: chemicalbook)

Luo Xiaozhou told SciPhi-SynBio that the feature of Synceres platform lies in its full chain, and all R&D techniques are closely linked. “We don’t buy equipment for vague goals, but rather to achieve specific techniques by cleverly combining automation equipment with synthetic biology methods. Therefore, regardless of the type of final products being produced, as long as one follows the industry-leading database accumulated by Synceres, which includes key genes of the strains and the evolution of pathways, and identifies the metabolic pathway of the product, then selects the most appropriate chassis strain, and utilizes the highly efficient technique developed, it is possible to achieve an efficient commercial transformation of a specific product.”

Products Are Chosen Based on Market Needs, with Three Products Already Launched.

With the above-mentioned R&D techniques, using brewing yeast as the chassis cell, Synceres has produced three products: cannabidiol, cannabigerol and liquid synthetic rubber. “Developing products based on market needs does not mean that Synceres will produce whatever the market needs. Before deciding to develop a high-value product, Synceres will conduct a thorough pre-development assessment.”

Cannabinoid is a psychoactive drug with anti-spasm, anti-anxiety and neuroprotective effects. It is estimated that by 2024, the global market size of cannabis industry will increase to 58.7 billion US dollars. Previously, Luo Xiaozhou successfully established a full biosynthetic pathway for cannabinoids during his postdoctoral study under Professor Jay D. Keasling at the University of California, Berkeley, with his research results published in Nature. Since the establishment of Synceres, the team has modified brewing yeast multiple times, and the yield of cannabinoids has now exceeded the initial estimate by nearly a million times.

Picture | Cannabis (Source: waters)

Liquid synthetic rubber serves as a prime example.

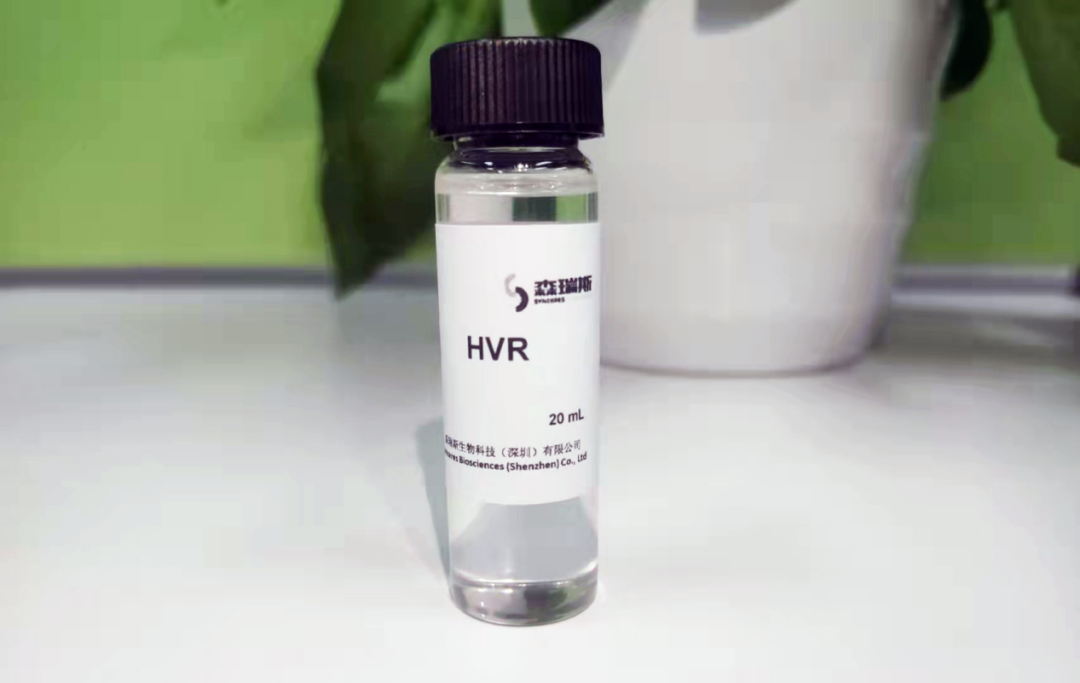

Also known as "liquid gold", this material is an additive to rubber that enhances its performance, improving grip and wear resistance.

“When Zhou Xibin, CEO of Synceres was conducting market research, he discovered that liquid synthetic rubber had a vast market. After discussing with the R&D team, he learned that brewing yeast could be used as a chassis cell to construct pathways to produce this new material, so it was decided to prioritize its research and development.” Leveraging several techniques previously developed for modifying brewing yeast, and in combination with their internal library of synthetic biological elements, Synceres managed to elevate the production of liquid rubber HVR to a commercial level in just six months.

Picture | HVR Products Produced by Synceres (Source: Synceres)

According to Luo Xiaozhou, pilot tests with a 1.5-ton fermenter have been completed for all three products.

In addition to these, Synceres is also developing other products such as key ingredients used for health care products, a non-protein amino acid used in the food and pharmaceutical industry and an ingredient for skincare. Notably, the non-protein amino acid is the world's first to be produced using synthetic biology methods and comes at a lower cost. In the future, Synceres will also produce more products applied in agriculture, aerospace, and bioelectronics."

In conclusion, regarding the booming synthetic biology market, Luo Xiaozhou shared his insights. The synthetic biology industry in China is still in its nascent stages, and there's much room for growth. Moving forward, there's a need to develop advanced technologies and pioneering concepts, bridging the gap between scientific research and industry.

References: http://www.synceres.com/product.aspx?cid=3